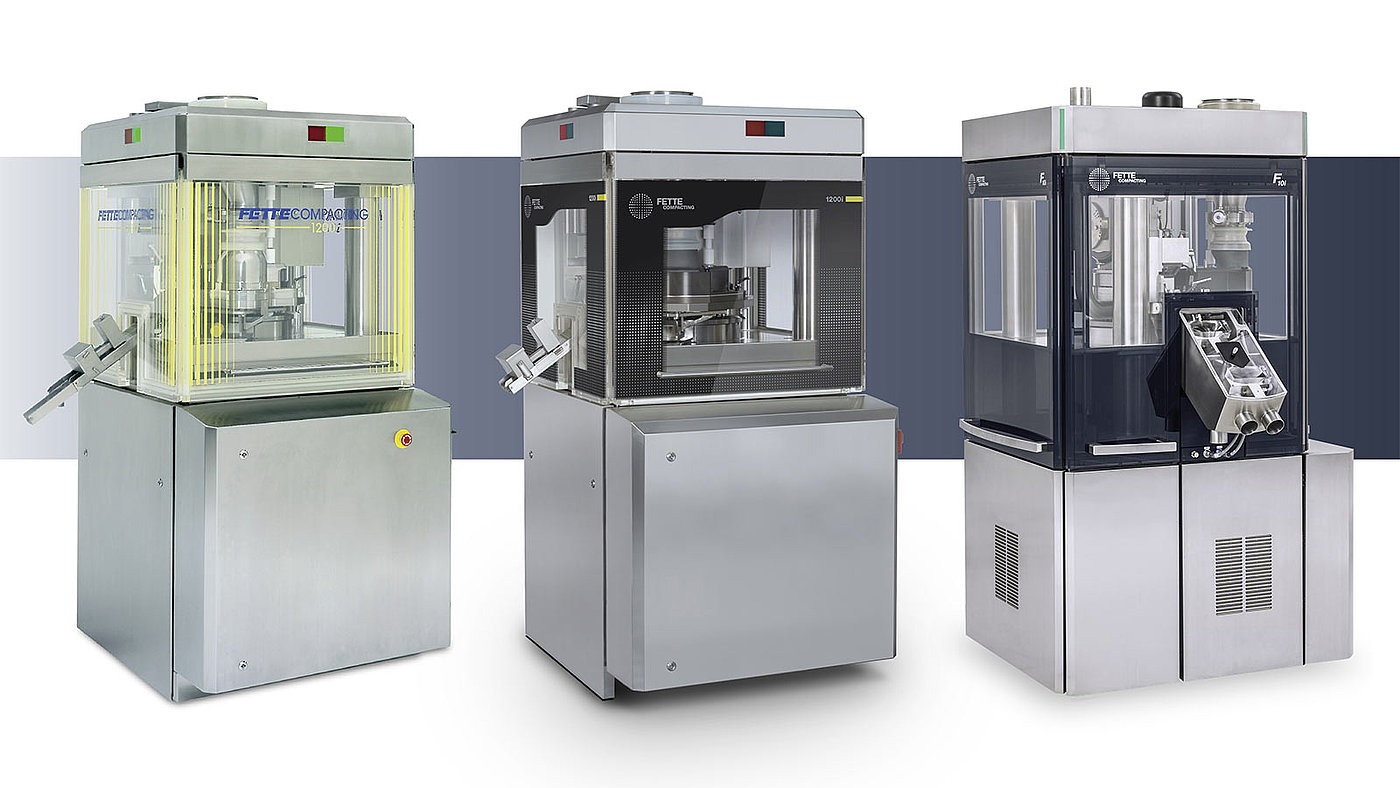

This is the last chapter of an illustrious career. In summer 2021, the last 1200i left the plant in Schwarzenbek and embarked on its journey to a customer in Malaysia. For Fette Compacting, this marks much more than the end of an item of corporate history. After all, the 1200i is not just any old tablet press among many others. It is one of the most successful machines the company has produced.

With its compact format, flexible application and short conversiontimes, this high-performance single rotary press was a popular choice for contract manufacturers and smaller customers in particular. “We hit the mark with the 1200i,” claims Jörg Gierds, Senior Product Manager at Fette Compacting. “It can be used in production, galenics or laboratories. It is small, versatile, ready for use in a short space of time, and exceedingly mobile thanks to its integrated switching cabinet. All features which made it very popular up until the end.”

Just how well Fette Compacting hit the nail on the head in the form of the 1200i became obvious shortly after sales commenced in 1994. The sales figures rose swiftly after only a short time. Many machines were used by customers. “The 1200i was an international best-seller,” claims Gierds. “Many of the machines were deployed in France and Germany. But they were and are also very popular in South America and Eastern Europe.”

Developed for the future

Jörg Gierds thinks it is appropriate that the last 1200i will be operating in Malaysia: “In recent years, Asia has become one of the most important production locations for the pharmaceutical industry. The fact that a successful machine such as our 1200i is to make its last appearance there is a wonderful reflection of the developments in the market.”

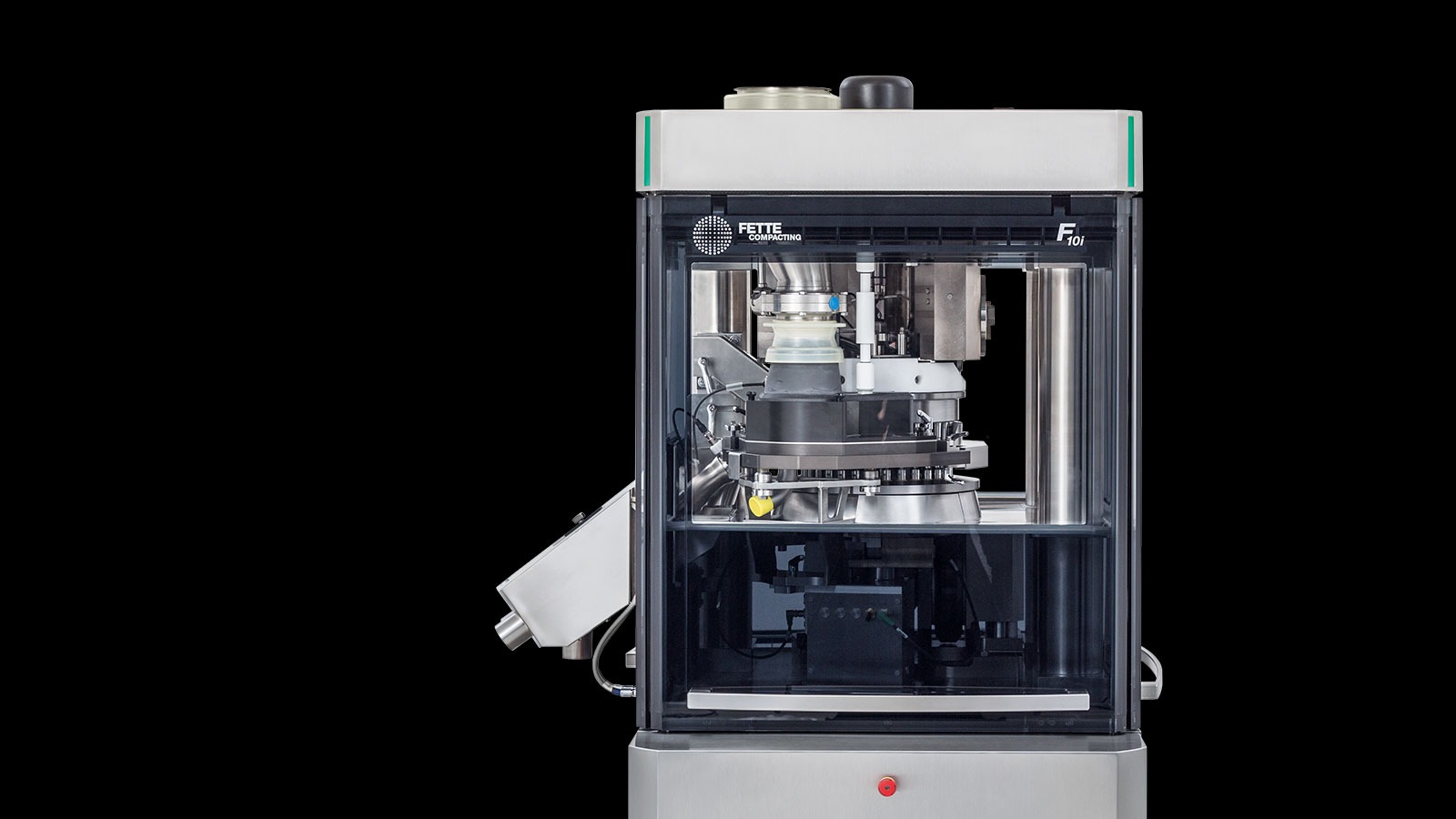

But Jörg Gierds does not feel too much melancholy regarding the end of the 1200i. He knows, after all, that Fette Compacting already has a more than worthy successor on the market. The F10i, the single rotary press in the new i Series, is an innovative development of the classic i Series. Apart from the discontinued 1200i, this range also includes the 2200i, 3200i, 2090i and 3090i models which are all still available.

Numerous new features - from dust-tight standard designs to digital connectivity - make the F10i and indeed the entire new i Series the gold standard for pharmaceutical production of the future. Designed as an equally efficient and versatile machine for smaller batches, the F10i offers numerous innovative features. One of these is its crossgeneration system compatibility, which is a mark of all tablet presses in the new i generation.

Despite its modern machine design, all parts of the F10i with product contact are identical to those of the old i Series. Dies and segments turrets can therefore be adopted from the tablet presses of previous generations, as can entire turrets. This compatibility measurably minimizes the effort involved in validation and qualification. Thanks to their horizontal integrability, the new tablet presses are perfect fits in existing production environments: old and new machines, such as the 1200i and the F10i, work efficiently side by side.

Fit for the future: the tablet presses in the new i Series are connectible, system-compatible and dust-tight as standard.

Connectible and dust-tight

Furthermore, the F10i also features technical connectivity for state-ofthe-art production environments, even up to so-called Pharmaceutical production 4.0. This includes process equipment integrated via plug-and-play as well as open interfaces for connections to the internet of things (IoT) and for a Manufacturing Execution System (MES).

Software solutions facilitate operation of the tablet press. A human machine interface permits intuitive control and monitoring of the machine and process equipment, while a workflow wizard guides users through standard procedures. Via a mobile app, the production process can be monitored in real time independent of its location.

As operator protection is steadily gaining in importance, the F10i, as well as the larger F30i, are already consistently dust-tight even in their standard versions, starting with the press room through to the connections between the machine and its process equipment. This not only protects operators from active substances but from any type of exposure.

“In the form of the F10i, we have built a machine which fully complies with the requirements on modern pharmaceutical production,” is how Gierds summarizes the new product. “The 1200i has successfully passed the baton to the machines in the new i Series.”

»THE 1200I HAS SUCCESSFULLY PASSED THE BATON TO THE MACHINES IN THE NEW I SERIES.«

Jörg Gierds, Senior Product Manager at Fette Compacting